Ever power

Cyclo Motor

One

Among the electrical equipment of the same voltage level, the impulse withstand voltage level of the insulation of the rotating motor gearbox is the lowest.

Two

The residual voltage of the arrester used to protect the rotating motor is very close to the impulse withstand voltage of the motor, and the insulation margin is very small.

Three

In turn to turn insulation, the steepness of inrush wave is strictly limited.

Ever Power

Products

Swing motor gear sumitomo cyclo spg

Output Power:6—-250W

AOKMAN WB Series Small Cyclo Gear Reducer Motor

Rated Power:0.04~3KW

BWD XWD sumitomo gearbox Cyclo cycloidal Drive Speed Reducer Motor

Rated Power:0.12~200kw

Ever Power

Show More

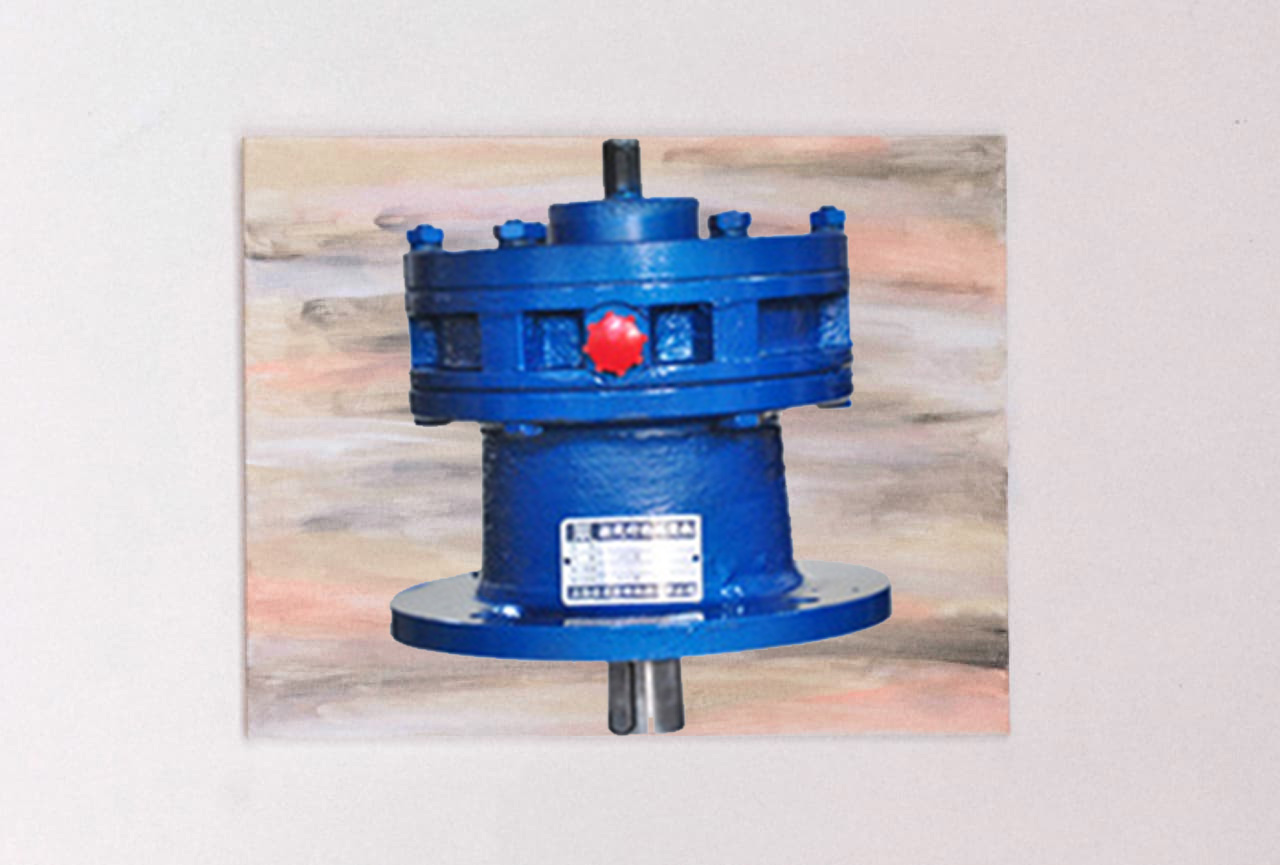

Vertical cyclo motor gearbox XL/BL

Rated Power:0.37kw—45kw

Input Speed:0–1500r/min

Output Speed:0–170r/min

Place of Origin:China

Model Number:BL/XL

Brand Name:EP

f series ac shaft motor speed cyclo drive reducer reducer gearbox motor

Gearing Arrangement:Helical

Output Torque:200-18000N.M

Rated Power:0.12-200KW

Input Speed:750-1500 rpm

Output Speed:0.21-374rpm

Place of Origin:China

Model Number:Series F

Brand Name:EP

ever power

Cyclo Motor

There are many kinds of cyclo motors. It can be divided into generator and motor according to its function, DC motor and AC motor according to its voltage property, and synchronous motor and asynchronous motor according to its structure. Asynchronous motor can be divided into three-phase asynchronous motor and single-phase asynchronous motor according to the different number of phases; according to the different rotor structure, it can be divided into cage type and wound rotor type, among which cage type three-phase asynchronous motor is the most widely used and the largest demand in various motors because of its simple structure, convenient manufacture, low price and reliable operation.

cyclo motor

Insulating material

Impregnating paint

It is used for impregnating motor windings and fiber materials to improve the electrical performance, thermal conductivity, heat resistance, moisture resistance of insulation and the integrity of windings. In recent years, the development of solvent-free impregnating paint, the most widely used are polyester and epoxy, gradually replacing the cyanoalkyd paint.west.

Covering paint

Also known as brushing paint or coating paint, the paint is applied on the impregnated insulation surface to form a good mechanical performance, smooth and water-resistant insulation film, so as to enhance the moisture-proof ability and prevent the effect of dust, dirt and chemical substances on the insulation, such as enameled wire paint, silicon steel sheet paint, semi conductor paint, etc.

Adhesive paint

It is used to bond various insulating materials, such as mica, paper, cloth, etc. In addition to the electrical performance, especially the adhesive force. The commonly used adhesive paints are alkyd resin paint, shellac paint, phenolic resin paint, epoxy polyester paint, etc.